Intelligent Hardware Retail Range Door Viewer

Features Include:

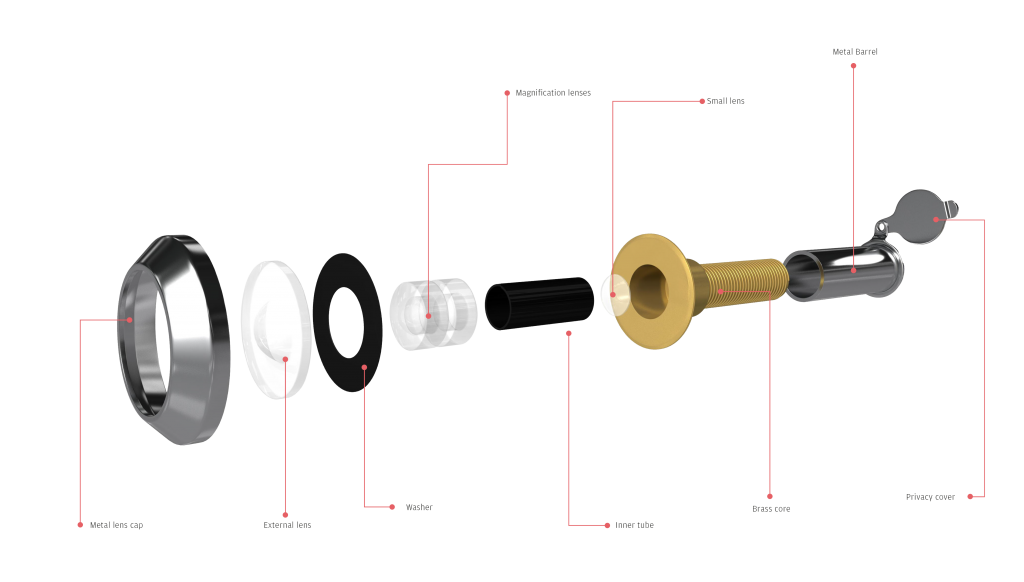

The Intelligent Hardware Viewer is a great security accessory, as no door should be opened without first checking who is on the other side. Available in PVD gold, mirror polished and satin stainless finishes. Both our composite and uPVC door viewers come with a free fitting tool.

This tool has been designed to fit on to the end of a drill bit, and makes it quick and easy for consumers to tighten the door viewer without having to screw it together manually.

- Secured by Design approved

- Comprises of 3 plastic lenses

- Tested to DHF TS002:2009

- Manufactured from grade 316 stainless steel

- LIFETIME coating guarantee

Available in:

PVD Gold

PVD Gold

Mirror Polished

Mirror Polished

Satin Stainless

Satin Stainless

- Overview

- Product Codes

- Technical Info

- Product Testing

- Product Videos

- Brochures & Tech Sheets

- Product Guarantee

- Troubleshooting

Features Include:

| Awarded 'Secured by Design' approval by the Association of Police Officers |

| Made of 316 grade stainless steel |

| Ensured to give crystal clear performance for years of safe, secure use |

| Comes in a range of colours to suite door furniture |

| Additional extensions available if you need to make your viewer even longer |

| LIFETIME guarantee |

Featuring a number of impressive designs and numerous finishes the Secured by Design Door Viewers range at UAP Ltd will look fantastic on any Composite or Wooden door!

Door viewers (spyholes) are a great security accessory for your customers, as no door should be opened without first checking who is on the other side. Door security is essential to ensuring a home is safe and once quality locks have been fitted it’s key to have a door viewer. Many homeowners overlook the importance of really seeing who is on the other side of the door and essentially this can actually be the best way to prevent unwanted guests, break-ins, and scams. Providing your customers with this important information will help them learn to better protect their homes and keep intruders out.

Each spyhole has gone through rigorous testing, and have each been tested to DHF TS002:2009 which covers Corrosion Resistance, Security (Angle of Vision), Visual Clarity, Resistance to Misting Up, Ability to Clear After Misting, Length Adjustment Range and Marking. The door viewers have also been awarded 'Secured by Design' by the Association of Chief Police Officers.

With a variety of wide angle Marine Grade door viewers homeowners will be able to select the viewer most suitable for their needs and overall home interior and exterior. Whatever their overall door hardware finish is there is a spyhole suitable to match it. Made of 316 grade stainless steel and comprising 3 glass lenses, each spyhole ensures to give crystal clear performance for years of safe, secure use.

The 12mm Wide Angle Marine Grade Door Viewers are made from 316 grade stainless steel and are part of the UAP Nanocoast range. The UAP Nanocoast range of products are specifically designed for areas which are within a 25 mile radius of the coast, or within 5 miles of highly populated industrial areas. Each door viewer has been salt spray tested to ASTM B117 for 2,000 hours, and comes with an industry first LIFETIME coating guarantee, as it will not pit, rust or corrode no matter what environments you put them in!

Product Codes:

12mm Wooden and Composite Door Viewers (35-55mm)

| Finishes | Product Code |

Material Construction |

Privacy Cover Included |

PVD Head |

Lens | Coating Guarantee |

| PVD Gold | CVPLPVDG-NANOCOAST-IHR | Stainless Steel | Yes | Yes | Glass | LIFETIME |

| Mirror Polished | CVPLMPSS-NANOCOAST-IHR | Stainless Steel | Yes | Yes | Glass | LIFETIME |

| Satin Stainless | CVPLSSS-NANOCOAST-IHR | Stainless Steel | Yes | Yes | Glass | LIFETIME |

12mm Wide Angle Marine Grade Door Viewers (38-63)

| Finishes | Product Code |

Material Construction |

Privacy Cover Included |

PVD Head |

Lens | Coating Guarantee |

| PVD Gold | CILPVDG38-63-NANOCOAST-IHR | Stainless Steel | Yes | Yes | Glass | LIFETIME |

| Mirror Polished | CILMPSS38-63-NANOCOAST-IHR | Stainless Steel | Yes | Yes | Glass | LIFETIME |

| Satin Stainless | CILSSS38-63-NANOCOAST–IHR | Stainless Steel | Yes | Yes | Glass | LIFETIME |

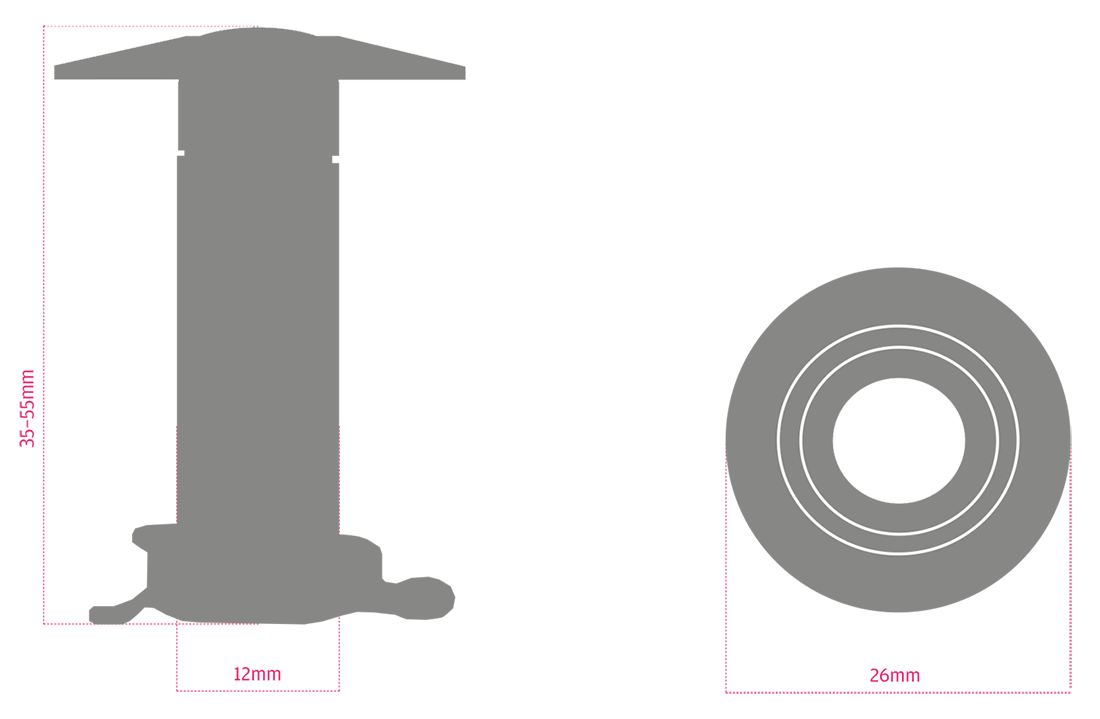

Technical Info:

(Click the below image to zoom in)

Sizes:

| Barrel Thickness | 12mm |

| Extension | 35-55mm |

| View Head Size | 26mm |

![]()

At UAP we are constantly striving to improve on the products we already supply as well as develop new, pioneering ranges and practical product solutions.

With an in house testing centre and product developer, each stage of the development process is thorough, from the initial design right down to the final product. In house 3D printing technology allows for further and more precise advancement of our products which are then expertly manufactured and put through stringent testing conditions using in house test equipment – ensuring all products are designed to the highest standards:

Salt Spray Test

This machine tests the corrosion resistance of the door viewers. The salt spray cabinet produces a corrosive environment, by releasing a dense saline fog into the chamber which the products are exposed to. This creates an accelerated corrosion of the product and allows us to test how well the door viewer would stand up in harsher environments.

The door viewers are tested for 2,000 hours where we offer a LIFETIME coating guarantee anywhere in the country, as the door viewers will not pit or rust.

All Weather Machine

When placed in the all-weather machine, the door viewers are subjected to conditions including high UV exposure using a Xenon Arc Lamp which will accelerate UV degradation and measure how well a door viewer can last in extreme conditions.

Other conditions such as rain and extreme heat can be generated by the machine to expose door viewers to all kinds of environments. This allows us to continually improve the door viewers and make them so they last longer in all kinds of different environments.

120 Degree Viewer Test

In order to meet Secured by Design specifications a door viewer must have a viewing angle of 120 degrees (60 degrees on either side). To test the angle of vision, the door viewer is fitted to a wooden block with a thickness of 45mm. The block is then fitted onto a protractor which is visible through the door viewer. The tester must look through the viewer and follow a stick, which they are holding, around the protractor until it is only just in sight through the viewer. This point must then be marked and the process is repeated on the other side. The test is conducted in accordance with DHF TS002:2009 standards.

DHF TS 002:2009 Test Report Data:

Corrosion Resistance

Door Viewer was subjected to a neutral salt spray test as detailed in BS EN 1670:2007 for 96 hours (grade 3).

| Comments | Grade |

| Minor red corrosion of cover | 3 |

Angle of Vision

The door viewer was mounted, in accordance with the manufacturer’s instructions, to a 45mm thick (+/-1mm) wooden block which, in turn, was mounted perpendicular to a protractor. Whilst looking through the door viewer, a point source of light was moved into view and the angle at which it first appeared (measured from a datum perpendicular to the “door” face) was noted. The test was repeated from the 180° opposite position and the two readings were added together to give an average “viewing angle” for the cone of vision.

| LH Reading | RH Reading | Angle of Vision | Grade |

| 46 | 49 | 95 | Unclassified |

Visual Clarity

The door viewer was mounted in a suitable test-rig in which the viewer was held perpendicular to a sheet of text at a distance of 150 mm. Using normal or corrected normal vision, in good light, attempts were made to read text in progressively smaller point sizes and the smallest point size that could be read was noted. (The font used was Arial Black – regular, printed using Microsoft Word).

| Reading B | Reading C | Grade |

| 10 | 10 | 3 |

Resistance to Misting Up

The door viewer was mounted, in accordance with the manufacturer’s instructions, to a 45mm thick (+/-1mm) painted wooden block – representing part of a typical external door to a dwelling. This, in turn, was mounted in a test-rig in which the viewer was held perpendicular to a sheet of text at a distance of 150 mm. Using normal or corrected normal vision, in good light, attempts were then made to read text in progressively reducing font sizes and the smallest point size that could be read was noted. The wooden block was then stood upright in an environmental chamber and subjected to 72 hours of cyclic humidity to BS 3900-F2:1973. Immediately after the humidity test, the readability test was repeated by the same person.

| Initial Reading B | Initial Reading C | Reading B | Reading C | Grade |

| 10 | 10 | None | None | 1 |

Ability to Clear After Misting Up

Following the humidity test, the door viewer (still in the wooden block) was allowed to dry out for 72 hours at 30° C, after which the readability test was repeated by the same person who carried out the initial test.

| Initial Reading B | Initial Reading C | Reading B | Reading C | Grade |

| 10 | 10 | 10 | 10 | 3 |

Length Adjustment Range

The door viewer was screwed up to its shortest length and the distance between the mounting flanges noted. It was then unscrewed so that there was a full turn of engagement on all threaded connections and the distance between mounting flanges was again noted.

| Minimum Length | Maximum Length | Grade |

| 34.8 | 60.1 | 35-60 |

Door Viewer Guarantee:

UAP Ltd distribute a wide range of door viewers, made from brass, aluminium and Nanocoast 304 or 316 grade stainless steel.

The door viewers are available in a range of colours, and we guarantee the door viewers and finishes against the following:

Surface Coating Failure

Coating Guarantee = the sooner of “the guarantee supplied for the door or window from the manufacturer” or “5 years inland” on brass and aluminium based door viewers or “Lifetime” on Nanocoast 304 or 316 grade stainless steel based door viewers.

We guarantee that the door viewers will not tarnish on the door for the guarantee period given above subject to;

1. The door viewers are applied to a door or door panel, and no item of door furniture on the door or door panel are sealed or fixed using any form of silicone sealant or the like.

2. The door viewers are fixed correctly and the right way around using the correct fixings, and are not scratched or damaged at any time during the installation process or thereafter.

3. Nanocoast 304 or 316 grade stainless steel based door viewers are cleaned with a lemon based very mild soap solution and a soft cloth once a month, or every 2 weeks in areas of high sea salt such as coastal areas. At no point should any form of cleaning agents be used.

4. Brass and aluminium based door viewers are installed inland (defined as 25 miles from the coast or 5 miles from highly populated industrial areas) and are cleaned monthly with a moist cloth. At no point should any form of cleaning agents be used.

5. No claim will be accepted for any door viewer that is scratched or mutilated or fitted incorrectly.

6. The guarantee only applies if the door viewer is fixed to the original door for which it was bought and fitted by the installer. The guarantee will cease immediately if the door viewer is removed from the original door or door panel.

Mechanical Failure

Mechanical Guarantee = the sooner of “the guarantee supplied for the door or window from the manufacturer” or “5 years inland” on brass and aluminium a based door viewers or “10 years” on Nanocoast 304 or 316 grade stainless steel based door viewers.

We guarantee that the door viewers will not fail mechanically the door for the guarantee period given above subject to the conditions outlined above.

Claiming Under the Guarantee

Every product must be inspected before they are fitted on to a door, window frame or door panel for any defects. If any defects are found then the product must not be fitted and the fault reported immediately to UAP Limited. Any product fitted is assumed to have been inspected and approved as being fit for purpose.

To make a claim under the guarantee, UAP Limited must receive in writing the product code of the item, the full details of the problem, the date the product was purchased, the date of manufacture of the unit in question and the address of the installation.

We will require all ‘faulty’ items to be sent to ourselves at the address below by first class recorded delivery post. We will then examine the item in question and confirm whether the item is covered by the guarantee. If it is not covered by the guarantee we will advise you, the customer, in writing of the reason for rejecting the claim.

Limitations of the Guarantee

UAP Limited’s guarantee will be limited solely to the replacement of the item purchased from UAP. There is no liability whatsoever for consequential damages or costs, howsoever calculated or incurred. UAP Limited will enforce and rely fully upon their terms and conditions of sale in all aspects other than the limitation set out above. UAP will also pay for the cost of the recorded delivery, if and only if, the product is deemed to be covered by the terms of the guarantee set out above.

Payment of the Guarantee

UAP reserve the right to discharge the guarantee claim in the form of replacement products at the customer’s normal buying price at the time of the complaint being received by UAP Limited.

Time Limit on Guarantee Claims

UAP will only be liable for claims made within a maximum period of 10 years from the date of purchase of the products from UAP Limited.

Correspondence Address for all Guarantee Claims

Any guarantee claim must adhere to the system set out above in all respects and must be made in writing to: UAP Limited, Orbital 60, Dumers Ln, Bury, BL9 9UE.

The terms of this guarantee may be varied by UAP Limited at any time at our own discretion. Please see www.uapcorporate.com for up to date product guarantees.