Fullex Slam Shut Autolock

Features Include:

Based on the popular Crimebeater lock, the Slam Shut Autolock has an actuator unit positioned between the centre case and the top bolt. When combined with bespoke intumescent kits, the Slam Shut Autolock has achieved FD30 and FD60 on timber doorsets and FD30 on composite.

- For use on timber and composite doors

- Based on the Fullex Crimebeater lock

- Dual spindle

- Easily reversible latch as standard

- Supplied with complete with strike plate

- Tested to 50,000 full cycles

- Corrosion resistance tested to BS EN 1670 Grade 5 for 480 hours

- Holds Police Preferred Specification and is accredited by Secured by Design

- Can be used as a critical component with PAS 24

- Comes with a 10 year mechanical guarantee

- 1 hour fire rated

- Overview

- Product Codes

- Technical Info

- Product Testing

- Brochures & Tech Sheets

- Product Guarantee

- Troubleshooting

For use on Single Doors

For use on Single Doors

Features Include:

| 60 minutes fire rated |

| Designed for use on timber and composite doors |

| Comes with a dual spindle lock |

| Easily reversible latch as standard |

| Supplied complete with strike plate |

| Tested to 50,000 full cycles |

| Resistant to corrosion - BSEN1670 Grade 5 (480 hours) |

| Comes with a 10 year guarantee |

Fire Testing Standards:

| Protection Time | Door Material |

| FD60 - 60 Minutes | Timber |

| FD30 - 30 Minutes | Timber |

Based on the popular Crimebeater lock, the all new Autolock fire door slam shut door lock is engineered to provide long term reliability and security. It has an actuator unit positioned between the centre case and the top bolt. When the door is closed a trigger in the actuator is depressed by a strike plate fitted to the outer frame which allows the actuator to drive the top and bottom bolts into their extended position. A single rotation of the key then locks the door.

Available in dual spindle for use with 92mm/92mm or 92mm/62mm long backplate handles and is supplied complete with strike plate.

The Fullex Autolock fire door slam shut lock is also perfect to combine with the Kinetica 3* Kitemarked Euro Cylinder, giving you a solution that offers high security, reliability and easy operation:Product Codes:

Autolock:

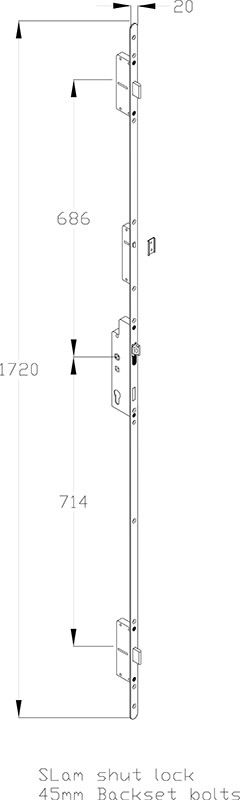

Faceplate = 1720mm x 20mm (Zinc and Clear Passivated Steel) – Radius Ends

| Product Code | Spindle | Backset Size |

Handle Backplate |

Handle Centres |

No of Deadbolts |

No of Hooks |

Hook Direction |

| FULLEX-CRB-AUTOLOCK | Dual | 45mm | 243mm | 92mm or 92/62mm |

3 | 0 | – |

Technical Info:

Technical Data:

| Corrosion Resistance | BS EN1670 Grade 5 (480 Hours) |

| Cyclic Operation | Cycle Tested to 50,000 Cycles |

Materials:

Top and Bottom Deadbolt: Chrome plated A3 hardened cast steel

Centre Deadbolt: CZ 122 Brass stamping

Faceplate and Gearbox: Zinc and clear passivated mild steel

![]()

Cyclic Operation

The cyclic operation machine tests the operation and use of each multi point lock. The machine works by fitting the multi point lock in to a door, and then adding a handle and cylinder. The machine will then cycle test the lock by turning the cylinder to unlock; pull the handle down to open the door; close the door; lift the handle to engage the multi point hooks, and then finally lock the cylinder. This gives a true test of how the multi point lock will work in a real life situation.

Each multi point lock is cycle tested to 50,000 cycles.

Salt Spray Test

This machine tests the corrosion resistance of the multi point locks. The salt spray cabinet produces a corrosive environment, by releasing a dense saline fog into the chamber which the multi point locks are exposed to. This creates an accelerated corrosion of the MPL and allows us to test how well the locks would stand up in harsher environments.

The multi point locks are tested to BS EN1670 grade 5 for 480 hours.

Product Guarantee

We guarantee the multi point lock and finish against the following;

Surface Coating Failure

We guarantee that the multi point locks have a 5 year inland coating guarantee (defined as 25 miles from the coast or 5 miles from a highly populated industrial area) subject to;

1. The multi point locks are applied to a door and no item of door furniture on the door or window frame are sealed or fixed using any form of silicone sealant or the like

2. The multi point locks are fixed correctly using the correct fixings and are not scratched or damaged at any time during the installation process or thereafter

3. The multi point locks are cleaned monthly with a moist cloth and not with any form of cleaning agent

4. The internal workings are lightly sprayed with 3 in 1 or a light machine oil (or similar) every 12 weeks

5. No claim will be accepted for any multi point lock that is scratched or mutilated or fitted incorrectly

Mechanical Failure

We guarantee that the multi point locks will not fail mechanically in normal use during the 10 year guarantee period subject to the conditions outlined above.