UAP High Security 1* Kitemarked Euro Half Cylinder

Features Include:

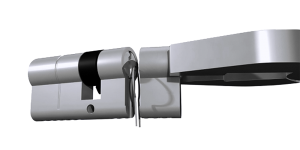

The 1* Kitemarked half euro cylinder is available in a black finish and has been designed for locks that need to be opened or locked from one side only. Ideal for garage doors, patio doors, stock cupboards etc.

- BSi 1* Kitemarked

- Secured by Design approved

- Supplied with 3 keys

- Sacrificial cut, anti-bump, anti-drill and anti-pick

Available in:

Black

Black

Brass

Brass

Nickel

Nickel

Chrome

Chrome

- Overview

- Product Codes

- Technical Info

- Product Testing

- Product Videos

- Brochures & Tech Sheets

- Product Guarantee

- Troubleshooting

Features Include:

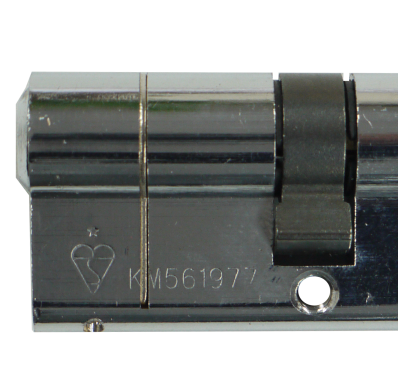

| BSi 1* Kitemarked - KM561977 |

| Secured by Design approved |

| Supplied with 3 keys |

| Has 6 pins |

| Designed for locks that need to be opened or locked from one side only |

| Ideal for garage door locks, patio door locks, stock room cupboard locks, broom cupboard locks, caretaker storage room locks etc. |

| Has a sacrificial cut line |

| Patented anti-bump feature |

| 3 anti-pick pins |

| 4 hardened steel anti-drill pins |

| Unrestricted keyway makes it easier for customers to get keys cut using the UAP key blank |

| Restricted section keyways available in a range of sizes |

| Over 800,000 different key combinations! |

| Can be keyed alike or mastersuited to Kinetica 3* cylinders and UAP rim cylinders |

| Tested to EN1303:2005 |

The UAP+ half cylinder is the best choice for inexpensive home security installation. Created in accordance with the British Standards Kitemark, and also awarded the "Secured by Design" approval by the Association of Police Officers, the high quality 6 pin Kitemarked euro half cylinder can be fitted to any external door in order to ward off criminals that attempt to use the most popular break-in methods.

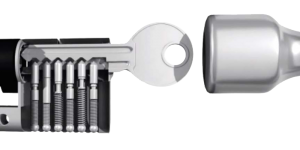

Each half cylinder is packed full of security features, and is part of UAP's super smooth cylinders using the Chris Belcher designed anti-bump timing pin system. This very clever system uses nickel plated hardened steel key pins and driver pins, which gives the anti-drill feature we wanted to incorporate. The Patented timing pins are designed to interrupt the timing of the pins when bumped, and it is highly effective. And because we use special pins rather than trap pins, we do not have a high expense to get this anti-bump feature! The timing pins have inbuilt anti-picks, and mushroom driver pins, which makes them highly effective against picking.

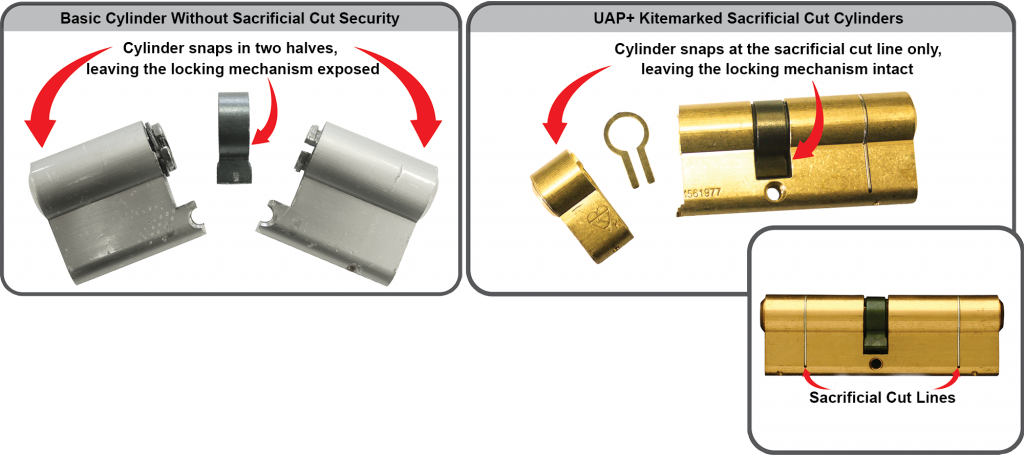

The cylinders also have a sacrificial cut line on them. If force is applied to the end of the cylinder in an attempt to break the cylinder to gain access, on standard cylinders, the weakest part of the cylinder is the screw hole which is in the centre of the cylinder (as there is less metal here). When force is applied, the cylinder will break away at this screw hole, making it very easy to manipulate the cylinder into opening. On the UAP Double Kitemarked Euro Cylinder, the cylinder will break away to the sacrificial cut line only, leaving the locking mechanism intact. If the cylinder is broken at this sacrificial cut line, the last 2 pins in the chamber remain in the cylinder, meaning that the cylinder can still be locks and unlocked with the key.

We have in-house locksmiths which offer you the option to have keyed alike cylinders, or create customised and complex mastersuite systems.

Product Codes:

Single Side Cylinders

| Overall Size | Split (X-10-X) | Split (X/X) | Black Finish | Chrome Finish | Brass Finish | Nickel Finish |

| 40mm | 25-10-5 | 30/10 | ZL25/5BLACK | – | – | |

| 45mm | 30-10-5 | 35/10 | ZL30/5BLACK | – | – | |

| 50mm | 35-10-5 | 40/10 | ZL35/5BLACK | – | ZL35/5BAS | ZL35/5NAS |

| 50mm | 35-10-5 | 40/10 | – | ZL35/5CAS | – | |

| 60mm | 45-10-5 | 50/10 | – | – | – | ZL45/5NAS |

| 85mm | 70-10-5 | 75/10 | – | – | – | ZL70/5NAS |

Thumb Turn Cylinders

| Overall Size | Split (X-10-X) | Split (X/X) | Black Finish | Chrome Finish | Brass Finish | Nickel Finish |

| 45mm | 30T-10-5 | 35T/10 | – | – | – | ZL30T/5NAS |

| 50mm | 35T-10-5 | 40T/10 | – | ZL35T/5CAS | ZL35T/5BAS | ZL35T/5NAS |

| 85mm | 70T-10-5 | 75/10 | – | – | – | ZL70T/5NAS |

Technical Info:

SACRIFICIAL CUT

The cylinder has a sacrificial cut line, so when force is applied to the end, the cylinder will break away to the sacrificial cut line only, leaving the remaining cylinder operational and the locking mechanism intact.

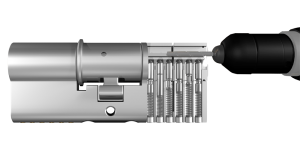

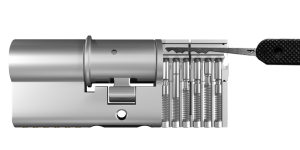

ANTI-BUMP

The cylinder has a unique and patented anti-bump system which does not use trap pins. This system makes the turning of the cylinder key extra smooth.

ANTI-DRILL

4 x hardened steel anti-drill pins are in each side of the cylinder. Plus all moving pins are nickel plated hardened steel 50 HRC minimum.

ANTI-PICK

Minimum of 3 anti-pick pins in each side of the cylinder makes it extremely difficult for a common burglar to pick the cylinder.

![]()

At UAP we are constantly striving to improve on the products we already supply as well as develop new, pioneering ranges and practical product solutions.

With an in house testing centre and product developer, each stage of the development process is thorough, from the initial design right down to the final product. In house 3D printing technology allows for further and more precise advancement of our products which are then expertly manufactured and put through stringent testing conditions using in house test equipment – ensuring all products are designed to the highest standards:

Cylinder Cycle Machine

This sophisticated machine tests the rotational operation of cylinder locks, ensuring a lock will continue to function even after being used in thousands of openings. It replicates the action of a key being inserted into the cylinder and it being turned, just as a product would be operated when fitted into a door. The product is tested to 100,000 repetitions to ensure it continues to function even after thousands of turns. It allows UAP to perform tests in accordance with BS EN 1303:2015 standards.

Cylinder Snapping Test

In accordance with PAS24, the test challenges the security features of a cylinder. An attempt is made to gain access through the cylinder by defeating its protective features, and then applying twisting or bending force to snap the cylinder and access its mechanism. Typically, the handle will first be ripped off, and then mole grips are used to try and make a larger hole around the cylinder. The cylinder is then snapped and attempts are made to turn the cam. A tester has 3 minutes in total to remove all protective hardware and defeat the cylinder, and only certain tools can be used if it cannot be done in this time then the cylinder will pass.

Salt Spray Test

This machine tests the corrosion resistance of the door locks. The salt spray cabinet produces a corrosive environment, by releasing a dense saline fog into the chamber which the door locks are exposed to. This creates an accelerated corrosion of the door lock and allows us to test how well the lock would stand up in harsher environments.

All Weather Machine

When placed in the all-weather machine, the door locks are subjected to conditions including high UV exposure using a Xenon Arc Lamp which will accelerate UV degradation and measure how well a door lock can last in extreme conditions. Other conditions such as rain and extreme heat can be generated by the machine to expose the door lock to all kinds of environments. This allows us to continually improve the door locks and make them so they last longer in all kinds of different environments.

EN1303 Cylinder Report Data:

| Clause No. | Description | Compliance |

| 4.2 | Key Strength | Yes |

| 4.3 | Durability – grade 6 | Yes |

| 4.5 | Fire resistance | Yes |

| 4.7 | Corrosion resistance – grade C | Yes |

| 4.7.1 | General | Yes |

| 4.7.2 | Operation at extremes of temperature | Yes |

| 4.8 | Key related security – grade 6 | Yes |

| 4.8.2 | Minimum number of effective differs – grade 6 | Yes |

| 4.8.3 | Minimum number of movable detainers – grade 6 | Yes |

| 4.8.4 | Maximum number of identical steps – grade 6 | Yes |

| 4.8.5 | Direct coding on key – grade 6 | Yes |

| 4.8.6 | Operation of security mechanism | Yes |

| 4.8.7 | Torque resistance of plug/cylinder relevant to key related security – grade 6 | Yes |

| 4.9 | Attack resistance – grade 2 | Yes |

| 4.9.1 | Resistance to attack by drilling – grade 2 | Yes |

| 4.9.2 | Resistance to attack by chisel – grade 2 | Yes |

| 4.9.3 | Resistance to attack by twisting – grade 2 | Yes |

| 4.9.4 | Resistance to attack by plug/cylinder extraction – grade 2 | Yes |

| 4.9.5 | Torque resistance of plug/cylinder relevant to attack resistance – grade 2 | Yes |

| 7 | Marking – classification on | Yes |

KM561977 Kitemark Report Data: Classification:

| Category of Use | 1 |

| Durability | 6 |

| Door Mass | 0 |

| Fire Resistance | 0 |

| Safety | 0 |

| Corrosion Resistance and Temperature | C |

| Key Related Security | 6 |

| Attack Resistance | 2 – Only resistance to drilling in accordance with BS EN 1303:2005 4.9.1 and torque resistance of plug/cylinder in accordance with BS EN 1303:2005 4.9.5 are required for one and/or three star rated cylinders |

Requirements in BS 3621:2007

| Annex A Clause A5 | Achieved |

| Annex A Clause A6 | Achieved |

| Testing in accordance with PAS 24 – Security hardware and/or cylinder test | One star cylinders offers resistance to many types of attack. It is designed to be used in conjunction with 2 star security door hardware to ensure enhanced resistance to all commonly used attack methods. Therefore this product MUST be used in conjunction with 2 star security door hardware meeting TS007 to ensure security. |

Cylinder Guarantee:

UAP Ltd distribute a wide range of euro cylinders, rim cylinders and key blanks.

We guarantee the cylinders and finishes against the following:

Surface Coating Failure

Coating Guarantee = the sooner of “the guarantee supplied for the door or window from the manufacturer” or “2 years inland.”

We guarantee that the cylinders will not tarnish on the door for the guarantee period given above subject to;

1. The cylinders are applied to a door or door panel, and no item of door furniture on the door or door panel are sealed or fixed using any form of silicone sealant or the like.

2. The cylinder is fixed correctly and the right way around using the correct fixings, and are not scratched or damaged at any time during the installation process or thereafter.

3. The cylinder is installed inland (defined as 25 miles from the coast or 5 miles from highly populated industrial areas) and are cleaned monthly with a moist cloth. At no point should any form of cleaning agents be used.

4. The internal workings of the cylinder are lightly sprayed with WD40 (or similar) every 12 weeks.

5. No claim will be accepted for any cylinder that is scratched or mutilated or fitted incorrectly.

6. The guarantee only applies if the cylinder is fixed to the original door for which it was bought and fitted by the installer. The guarantee will cease immediately if the cylinder is removed from the original door or door panel.

Mechanical Failure

Mechanical Guarantee = the sooner of “the guarantee supplied for the door or window from the manufacturer” or “2 years.”

We guarantee that the cylinder will not fail mechanically the door for the guarantee period given above subject to the conditions outlined above.

Claiming Under the Guarantee

Every product must be inspected before they are fitted on to a door, window frame or door panel for any defects. If any defects are found then the product must not be fitted and the fault reported immediately to UAP Limited. Any product fitted is assumed to have been inspected and approved as being fit for purpose.

To make a claim under the guarantee, UAP Limited must receive in writing the product code of the item, the full details of the problem, the date the product was purchased, the date of manufacture of the unit in question and the address of the installation.

We will require all ‘faulty’ items to be sent to ourselves at the address below by first class recorded delivery post. We will then examine the item in question and confirm whether the item is covered by the guarantee. If it is not covered by the guarantee we will advise you, the customer, in writing of the reason for rejecting the claim.

Limitations of the Guarantee

UAP Limited’s guarantee will be limited solely to the replacement of the item purchased from UAP. There is no liability whatsoever for consequential damages or costs, howsoever calculated or incurred. UAP Limited will enforce and rely fully upon their terms and conditions of sale in all aspects other than the limitation set out above. UAP will also pay for the cost of the recorded delivery, if and only if, the product is deemed to be covered by the terms of the guarantee set out above.

Payment of the Guarantee

UAP reserve the right to discharge the guarantee claim in the form of replacement products at the customer’s normal buying price at the time of the complaint being received by UAP Limited.

Time Limit on Guarantee Claims

UAP will only be liable for claims made within a maximum period of 10 years from the date of purchase of the products from UAP Limited.

Correspondence Address for all Guarantee Claims

Any guarantee claim must adhere to the system set out above in all respects and must be made in writing to: UAP Limited, Orbital 60, Dumers Ln, Bury, BL9 9UE.

The terms of this guarantee may be varied by UAP Limited at any time at our own discretion. Please see www.uapcorporate.com for up to date product guarantees.