UAP Slim Black Pull Handle

Features Include:

The UAP Slim Black Pull Handle is using a 32mm bar against a 32mm straight bar which create a more sleek and stylish product. The bolt through fixing gives a neater finish and as Stainless Steel 316 is used, the product will not rust and so there will be no leakage if it rains. Each straight pull handle comes with an Allen Key and 2 Allen Bolts on each of the up-stands. The handles are made from 316 grade stainless steel powder coated. All the pull handles have two fixing points with an individual plate on each.

- Made from 1.5mm 316 grade stainless steel

- 32mm diameter

- 3 fixing methods available – hidden fixings, bolt through and back to back

Available in:

Black

Black

- Overview

- Product Codes

- Technical Info

- Product Testing

- Product Videos

- Brochures & Tech Sheets

- Troubleshooting

Slim Black Pull Handle Features Include:

| Made from 1.5mm 316 grade stainless steel |

| 32mm diameter |

| High quality Black Powder Coating finish |

| All pull handles have two fixing points with an individual plate on each |

| Comes with an Allen Key and 2 Allen Bolts on each of the up-stands |

| 3 fixing methods available - hidden fixings, bolt through and back to back |

Using a 32mm bar against a 32mm straight bar gives a more sleek and stylish product. The bolt through fixing gives a neater finish and as Stainless Steel 316 is used, the product will not rust and so there will be no leakage if it rains. Each straight pull handle comes with an Allen Key and 2 Allen Bolts on each of the up-stands. The bolts are all made from 316 grade stainless steel. All the pull handles have two fixing points with an individual plate on each.

What makes the straight pull handle really stand out is the 3 different fixing methods available - hidden fixings, bolt though and back to back fixings. Due to the fixing methods, customers also have the option of sending the door to the site without the pull handle on, this will prevent damage in transit or on site. The door will simply be sent with the fixings on and the installation would be completed on site:

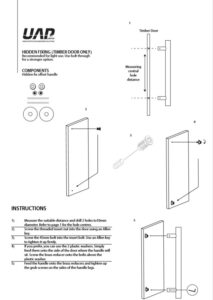

Hidden Fixings The pull handle comes with two fixing points each with an individual plate. These are fitted to wooden and timber doors using three screws. The pull handle then attaches to the plates and is secured with the Allen bolts. The internal fixings are not visible on the door!

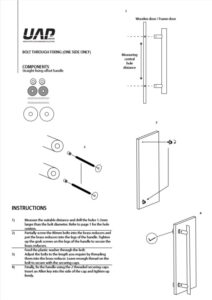

Bolt Through The bolt through method uses a brass thread reducer; this is included in one of the two accessory kits. The brass thread reducer has a 1.5mm thread on the outside which will thread into the upstand. On the internal of the reducer is an N8, this is an 8mm bolt through which provides an ideal position for an internal bolt to fit through. The two Allen bolts give extra protection against vibrations that may take effect on a main road causing bolts to come undone. With the Allen bolts this will not happen!

Back to Back We have developed a system which is incredibly easy to use and which will reduce fitting times to just seconds. Included in the second accessory kit is two plates which have holes all the way through. Once the plate is fitted on the inside of the door, the bolt can be pushed through the plate and screwed into the brass reducer. The internal pull handle would then be fitted using the hidden fix system. This offers an extremely strong back to back fixing method!

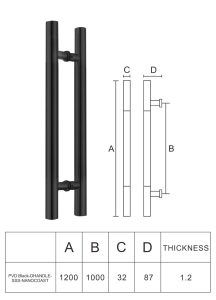

Product Codes:

| Size | STRAIGHT Product Code | OFF SET Product Code | Centres | Material Construction | Coating Guarantee |

| 900mm | PH900S-BLACK-SLIM | PH900OFF-BLACK-SLIM | 700mm | Stainless Steel | LIFETIME |

| 1200mm | PH1200S-BLACK-SLIM | PH1200OFF-BLACK-SLIM | 1000mm | Stainless Steel | LIFETIME |

| 1500mm | PH1500S-BLACK-SLIM | PH1500OFF-BLACK-SLIM | 1300mm | Stainless Steel | LIFETIME |

Sanding grain size: 80

Second sanding grain size: 120

Third sanding grain size: 180

Sanding belt size: 240

Color retention: 5 years

Chalk resistance: 5 years

Gloss retention: 5 years 30% retention

Erosion resistance: 5 years 10% retention

Dry film thickness: 1.0 mils minimum

![]()

At UAP we are constantly striving to improve on the products we already supply as well as develop new, pioneering ranges and practical product solutions.

With an in house testing centre and product developer, each stage of the development process is thorough, from the initial design right down to the final product. In house 3D printing technology allows for further and more precise advancement of our products which are then expertly manufactured and put through stringent testing conditions using in house test equipment – ensuring all products are designed to the highest standards:

UV Sunlight Testing Machine

Used to test the colourfast of plastic and anodised products, the UV machine measures the stamina of the pull handle finish, testing how quickly it will fade in sunlight. It does this using UV lights which the products are left under for 2000 hours.

Salt Spray Testing Machine

This machine tests the corrosion resistance of the pull handles and many other products. The salt spray cabinet produces a corrosive environment, by releasing a dense saline fog into the chamber which the products are exposed to. This creates accelerated corrosion to the product and allows us to test how well the product would stand up in harsher environments.