PAS24 & Document Q – Our Expert-Led Products

Published on 25 August, 2021

Latest News

Do you know how secure your door hardware really is?

PAS24 and Document Q are accreditations that guarantee a level of security for door and window hardware, monitored by certification bodies and regulations. They are both markers of quality and assurance for consumers. UAP provide a wide range of PAS24 and Document Q approved door and window products, as well as insights from industry experts that make our hardware as secure as can be.

![]()

What is PAS24?

PAS24 accreditation guarantees that the product and its production has been monitored by a UKAS (United Kingdom Accreditation Service) accredited certification body to ensure that it meets requirements for security performance. It indicates that these products are intended to resist the levels and methods of attack experienced in the UK and normally associated with the casual or opportunistic burglar.

PAS24 is a minimum standard, meaning that products that apply for PAS24 accreditation and surpass the minimum standard can officially be approved.

Should a product comply with PAS 24, this will enable compliance with Document Q of the building regulations.

What is Document Q?

Like PAS24, Document Q accreditation also indicates that the product is intended to resist opportunistic burglaries.

It supports Requirement Q1 of Schedule 1 of Building Regulations 2010 and only applies to new build dwellings.

Our Accredited Products

We provide a wide range of products that are approved by a variety of regulatory bodies, including the police initiative Secured by Design, BSI Kitemark, and Sold Secure Diamond.

Approved for PAS 24:

· Kinetica Helix TT 3* Kitemarked Euro Cylinder

Approved for Document Q:

· Kinetica Helix TT 3* Kitemarked Euro Cylinder

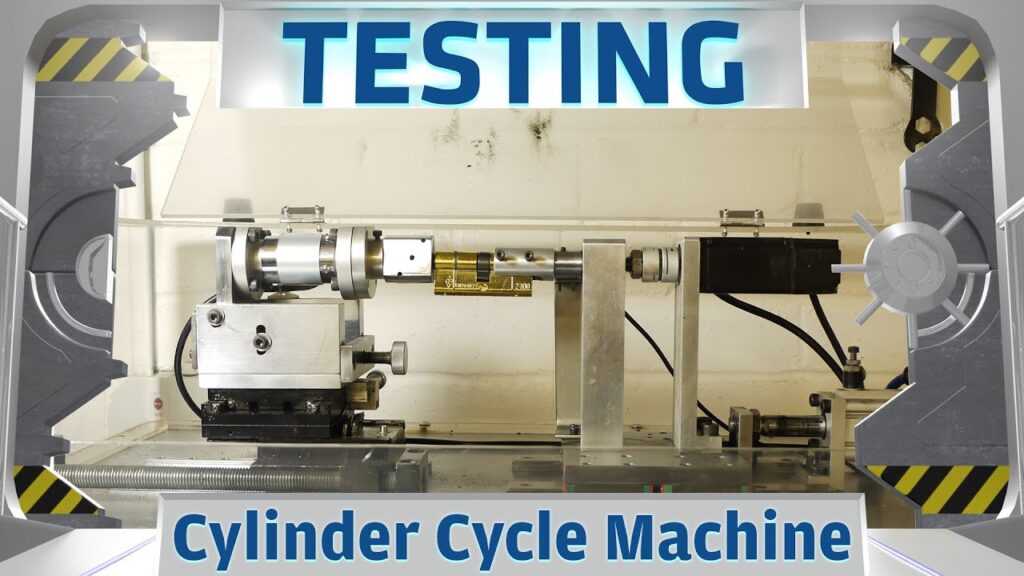

Example of UAP’s Testing Facilities

What our Experts Say

Our hardware is strenuously tested by our internal testing team, as well as by third-party accreditors such as PAS24 and Document Q.

In our final episode of the Hardware Intel Podcast, UAP’s Specifications Manager, Paul Goggins, spoke about third-party accreditation for fire doors and how testing has changed post-Grenfell, successfully reducing the number of fires that spread out of control.

UAP’s Product Certification Manager, Julian Roberts, explains how PAS24 and Document Q accreditation tests are conducted, and just how thorough they are:

· Infill Mechanical Test

A load of 2.0kN is progressively applied to every corner of the infill medium and each corner of the boundaries of components within the infill medium, in a direction towards the inside.

· Manipulation Test A

Attempts are made to gain entry by the hardware being operated, released, or disengaged.

· Manual Cutting Test

Attempts are made to gain entry by generating an aperture in the infill panel or the fabric of the door.

· Mechanical Loading Test

The objective of this test is to assess whether the sample can withstand a specified sequence of loading without creating an entry. This mechanically simulates an intruder attack using nail bars.

· Additional Mechanical Loading Test

This test is only conducted if entry is gained during the manual check test. This uses the same principle as the mechanical loading test.

· Manipulation Test B

The primary intention is to release threaded fasteners exposed as a result of the mechanical loading tests.

· Infill Manual Test

Attempts are made to remove gaskets, beads, security devices and the infill medium from the exterior face of the glazing system for a period of 3 minutes.

· Soft Body Impact Test

The objective of this test is to assess the door assembly’s resistance to impacts using a soft body (pendulum fall of a leather spheroconical bag of approximately 350mm diameter filled with dry sand to a total mass of 30kg) striking the door leaf between 800mm and 1700mm above floor level. Three impacts are conducted at three points. This simulates a body charge or an intruder kicking the door.

· Hard Body Impact Test

The objective of this test is to assess the hardware, infill medium and its retention system to a series of hard body impacts (pendulum fall of a cylindrical steel block having a mass of 50kg. Impacts are made at the following points, three at each point. On the lock cylinder when fitted, at each corner of the leaf at points 60mm x 60mm from the visible edge, on the door leaf at each locking point, on the door leaf at each hinge point, on a midrail (if present) at points 60mm from the joint with the stiles (if a vee joint is present impact 60mm from the point of the vee)at the centre of non-glass infill mediums and at each corner of the infill medium at points 60mm x 60mm from the visible edges. This simulates a sledgehammer attack.

· Security Hardware and Cylinder Test

The objective of this test is to assess the door furniture, hardware, and cylinder resistance to manual attack. The overall time allowed for this test is 10 minutes; the total attack time shall not exceed 3 minutes. The test consists of several activities, a) attempting to remove, dislodge or otherwise gain access to the cylinder by attacking any item protecting the cylinder, b) attempting to break or defeat the cylinder by applying a twisting or bending force and c) if access to the internal workings of the hardware, cylinder or lock is gained, then attempt to defeat the lock and gain access by operating any accessible mechanism. Attempts are also made to screw a self-cutting traction screw into any part of the exposed cylinder and then attempt to break and defect the cylinder by applying a nominally axial force to the screw using the hooked head attachment and torque gauge.

· Manual Check Test

The objective of this test is to explore the possibility that there might be weaknesses and vulnerabilities in the product that are not covered by the standard cases exists. The test is carried out from the exterior face of the sample. The tools available are two flat bladed screwdrivers and two nail bars.

UAP Stock Count: Important Notice

UAP Stock Count: Important Notice UAP Ltd Product of the Month: Crimebeater 220 Pro

UAP Ltd Product of the Month: Crimebeater 220 Pro Conquering Kilimanjaro for a Worthy Cause: Barry Halpin’s Journey

Conquering Kilimanjaro for a Worthy Cause: Barry Halpin’s Journey UAP Ltd Product of the Month: Fullex Key Wind Lock

UAP Ltd Product of the Month: Fullex Key Wind Lock UAP is Giving Away FREE Easter Eggs in the Run-Up to Easter 2024

UAP is Giving Away FREE Easter Eggs in the Run-Up to Easter 2024