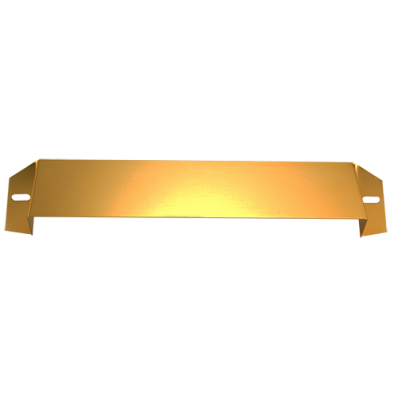

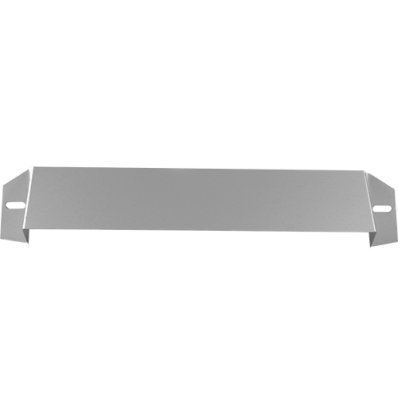

UAP Screw Fix Letterplate Restrictor Shrouds

Features Include:

The screw fix letterplate restrictor shroud will stop hands getting through letterboxes and ‘fishing’ for keys and more. This simple but effective device is 14.5″ long and stops the inner flap opening more than 40 degrees which stops unwanted hands being able to manoeuvre a rod inside.

- Great protection against key fishing

- Prevents rods being pushed through the letterbox

- Fits most letterplates (14.5″ long)

- PVD gold screw fix letterplate restrictor shrouds are part of the Nanocoast range

Available in:

PVD Gold

PVD Gold

Black

Black

Gold Anodised

Gold Anodised

Silver Anodised

Silver Anodised

- Overview

- Product Codes

- Technical Info

- Product Testing

- Product Videos

- Brochures & Tech Sheets

- Product Guarantee

- Troubleshooting

Features Include:

| Great protection against key fishing |

| Prevents the letterplate inner flap opening more than 40 degrees |

| Prevents rods being pushed through the letterbox |

| 14.5" long means it fits most letterplates |

| Available as part of the UAP Nanocoast range which comes with a LIFETIME coating guarantee! |

Key fishing or letterplate fishing is a technique burglars use to get hold of your keys, purse, handbags and more without even having to enter a property!

They simply push open your letterbox flaps and use a long hooked rod, similar to a fishing rod, to ´fish´ for your keys and handbags. Meaning they can then use the keys to just walk into your customer's property and help themselves to anything they want before driving off in their car!

The UAP screw fix letterplate restrictor Shroud will stop hands getting through your letterbox and either hooking your keys, or opening your lock. This simple but effective device is 14.5" long and stops the inner flap opening more than 40 degrees and so stops unwanted hands being able to manoeuvre a rod inside.

The PVD gold and mirror polished screw fix letterplate shrouds are made from 316 grade stainless steel, and is part of the UAP Nanocoast range. The UAP Nanocoast range of products are specifically designed for areas which are within a 25 mile radius of the coast, or within 5 miles of highly populated industrial areas. The identity card slot have been salt spray tested to ASTM B117 for 2,000 hours, and comes with an industry first LIFETIME coating guarantee, as the products will not pit, rust or corrode no matter what environments you put them in!

Product Codes:

| Finish | Product Code | Material Construction |

| Gold Anodised | SHGA | Aluminium |

| Silver Anodised | SHSA | Aluminium |

| PVD Gold | SHPVDG-NANOCOAST | 316 Grade Stainless Steel |

| Black | SHBL | Aluminium |

Technical Info:

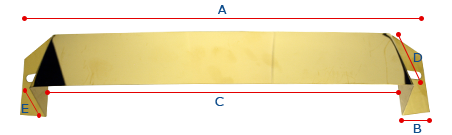

Letterplate Shroud Sizes:

| Overall Letterplate Shroud Length (A) | 400mm |

| Flap Length (B) | 30mm |

| Distance Between Inside Edges of Flaps (C) | 340mm |

| Letterplate Shroud Width (D) | 80mm |

| Protrusion from Door (E) | 40mm |

| Metal Thickness | 1mm |

| Restriction Angle | 40 Degrees |

| No of Screws Needed | 2 |

| Screws Supplied | No |

![]()

At UAP we are constantly striving to improve on the products we already supply as well as develop new, pioneering ranges and practical product solutions.

With an in house testing centre and product developer, each stage of the development process is thorough, from the initial design right down to the final product. In house 3D printing technology allows for further and more precise advancement of our products which are then expertly manufactured and put through stringent testing conditions using in house test equipment – ensuring all products are designed to the highest standards:

UV Sunlight Testing Machine

Used to test the colourfast of plastic and anodised products, the UV machine measures the stamina of the letterplate restrictor shroud finish, testing how quickly it will fade in sunlight. It does this using UV lights which the products are left under for 2000 hours.

Salt Spray Testing Machine

This machine tests the corrosion resistance of the letterplate restrictor shrouds and many other products. The salt spray cabinet produces a corrosive environment, by releasing a dense saline fog into the chamber which the products are exposed to. This creates accelerated corrosion to the product and allows us to test how well the product would stand up in harsher environments. Aluminium based products are tested to ASTM B117:2005 for 480 hours, where we offer a 5 year inland guarantee. Stainless steel products are part of the Nanocoast range, and are salt spray tested to ASTM B117:2005 for 2,000+ hours, and we offer a lifetime coating guarantee on these products.

Letterplate Shroud Guarantee

UAP Ltd distribute a range of ID card slots and letterplate shrouds, made from aluminium, zamak and Nanocoast 304 or 316 grade stainless steel.

The ID slots and letterplate shrouds are available in a range of colours, and we guarantee the ID slots and letterplate shrouds and finishes against the following:

Surface Coating Failure

Coating Guarantee = the sooner of “the guarantee supplied for the door or window from the manufacturer” or “5 years inland” on aluminium and zamak based ID slots and shrouds or “Lifetime” on Nanocoast 304 316 grade stainless steel based ID slots and shrouds.

We guarantee that the ID slots and shrouds will not tarnish on the door for the guarantee period given above subject to;

1. The ID slots and shrouds are applied to a door or door panel, and no item of door furniture on the door or door panel are sealed or fixed using any form of silicone sealant or the like.

2. The ID slots and shrouds are fixed correctly and the right way around using the correct fixings, and are not scratched or damaged at any time during the installation process or thereafter.

3. Nanocoast 304 or 316 grade stainless steel based ID slots and shrouds are cleaned with a lemon based very mild soap solution and a soft cloth once a month, or every 2 weeks in areas of high sea salt such as coastal areas. At no point should any form of cleaning agents be used.

4. Aluminium and zamak based ID slots and shrouds are installed inland (defined as 25 miles from the coast or 5 miles from highly populated industrial areas) and are cleaned monthly with a moist cloth. At no point should any form of cleaning agents be used.

5. No claim will be accepted for any ID slot or shroud that is scratched or mutilated or fitted incorrectly.

6. The guarantee only applies if the ID slot or shroud is fixed to the original door for which it was bought and fitted by the installer. The guarantee will cease immediately if the ID slot or shroud is removed from the original door or door panel.

Mechanical Failure

Mechanical Guarantee = the sooner of “the guarantee supplied for the door or window from the manufacturer” or “5 years” on aluminium and zamak based ID slots and shrouds or “10 years” on Nanocoast 304 or 316 grade stainless steel based ID slots and shrouds.

We guarantee that the ID slots and shrouds will not fail mechanically on the door for the guarantee period given above subject to the conditions outlined above.

Claiming Under the Guarantee

Every product must be inspected before they are fitted on to a door, window frame or door panel for any defects. If any defects are found then the product must not be fitted and the fault reported immediately to UAP Limited. Any product fitted is assumed to have been inspected and approved as being fit for purpose.

To make a claim under the guarantee, UAP Limited must receive in writing the product code of the item, the full details of the problem, the date the product was purchased, the date of manufacture of the unit in question and the address of the installation.

We will require all ‘faulty’ items to be sent to ourselves at the address below by first class recorded delivery post. We will then examine the item in question and confirm whether the item is covered by the guarantee. If it is not covered by the guarantee we will advise you, the customer, in writing of the reason for rejecting the claim.

Limitations of the Guarantee

UAP Limited’s guarantee will be limited solely to the replacement of the item purchased from UAP. There is no liability whatsoever for consequential damages or costs, howsoever calculated or incurred. UAP Limited will enforce and rely fully upon their terms and conditions of sale in all aspects other than the limitation set out above. UAP will also pay for the cost of the recorded delivery, if and only if, the product is deemed to be covered by the terms of the guarantee set out above.

Payment of the Guarantee

UAP reserve the right to discharge the guarantee claim in the form of replacement products at the customer’s normal buying price at the time of the complaint being received by UAP Limited.

Time Limit on Guarantee Claims

UAP will only be liable for claims made within a maximum period of 10 years from the date of purchase of the products from UAP Limited.

Correspondence Address for all Guarantee Claims

Any guarantee claim must adhere to the system set out above in all respects and must be made in writing to: UAP Limited, Orbital 60, Dumers Ln, Bury, BL9 9UE.

The terms of this guarantee may be varied by UAP Limited at any time at our own discretion. Please see www.uapcorporate.com for up to date product guarantees.